Xenon, krypton, and argon are known as noble gases, which are distinguished in chemistry for their non-reactivity with other substances. They are used in various industries, and their properties also allow their wide application in space-related technologies.

Xenon is the most commonly used noble gas in space missions due to its high efficiency as a propellant in Hall effect thrusters. On the other hand, while krypton and argon offer lower technical performance, some space companies choose them as alternative fuels due to their lower cost. However, specific thruster configurations using krypton (and in some cases argon) can also provide decent performance.

As we develop Hall effect thrusters and storage and feed systems, we need to analyze the attributes of these propellants and determine the configuration to use them most reliably and efficiently.

So, which of the noble gases is the best propellant? Let’s find out by looking at their properties, uses, benefits, and costs.

Comparing Noble Gases: Xenon, Krypton, and Argon

| Parameter | Unit | Value | ||

| Xenon | Krypton | Argon | ||

| Atomic mass | amu | 131.3 | 83.8 | 39.9 |

| Ionization energy | eV (kJ/mol) | 12.1 (1170.4) | 14.0 (1350.7) | 15.8 (1520.4) |

| Melting point | °K | 161.3 | 116.6 | 83.8 |

| Boiling point | °K | 166.1 | 119.6 | 87.3 |

| Critical temperature | °K | 289.7 | 209.3 | 150.7 |

| Critical pressure | kPa | 5842 | 5525 | 4863 |

| Critical density | kg/m3 | 1100 | 909.2 | 535.6 |

The main characteristics of xenon, argon, and krypton

Xenon

Xenon is a noble gas with a relatively high atomic mass. Its moderate ionization energy makes it suitable for use in ion propulsion systems. It is quite rare in the Earth’s atmosphere, with a concentration of approximately 87 parts per billion. The most common way to obtain xenon is using cryogenic distillation to extract and purify xenon from the air.

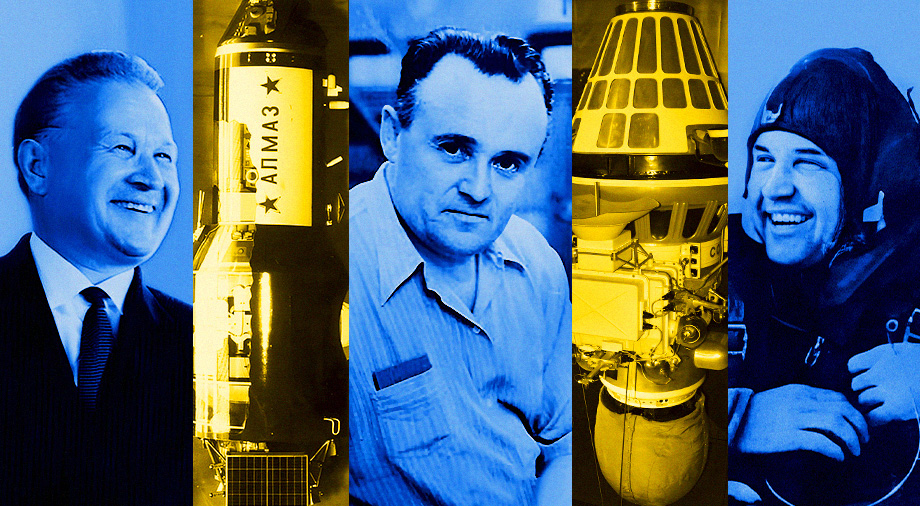

Credit: SETS

Krypton

Krypton has somewhat similar characteristics to xenon. Its molecular weight is 83.80, its concentration in the atmosphere of our planet is one part per million, and it is also extracted through cryogenic distillation.

Credit: SETS

Argon

Argon is far more prevalent in the Earth’s atmosphere. Its molecular weight is 39.95, which is much lower than that of xenon or krypton, and thus affects thruster parameters.

Credit: SETS

Noble Gases Applications and Cost

The space industry is not the main application for noble gases. Instead, they are primarily used for producing excimer laser systems, manufacturing superconductors, and as insulation in multi-pane windows. Xenon is also used in lighting systems, and argon protects against oxidation during welding.

Of all the three noble gases we are focusing on, argon is the most abundant, and therefore the least expensive. It comes as cheap as $7-$15 per kilogram, whereas krypton can cost $2,100-$4,800, and xenon can go as high as $5,000-$12,000 per kilo.

For more information, see the table below.

| Characteristic | Xenon | Krypton | Argon |

| Molecular Weight | High (131.30) | Moderate (83.80) | Low (39.95) |

| Availability | Very scarce | Somewhat scarce | Abundant |

| Cost | Very high | Somewhat high | Low |

| Applications | Excimer laser mixes, radiation, detectors, space propulsion, semiconductor manufacturing, lighting, space propellant | Window insulation, excimer laser systems, semiconductor manufacturing, space propulsion, lighting, space propellant | Steel manufacturing, semiconductor production, window insulation, welding, space propellant |

Xenon, Krypton, and Argon: Comparing Efficiency and Features

Xenon’s properties make it a perfect propellant in spacecraft propulsion systems. However, due to its limited availability and high demand for industrial applications, xenon has a relatively high cost, which affects the overall cost of operating electric propulsion systems which rely on it. Therefore, research is being conducted around the world into the use of alternative propellants that would reduce the cost of operating and maintaining electric propulsion systems while maintaining thruster performance at an acceptable level. Krypton and argon are the leading choices.

Let’s take a closer look at the specifics of using each of the propellants.

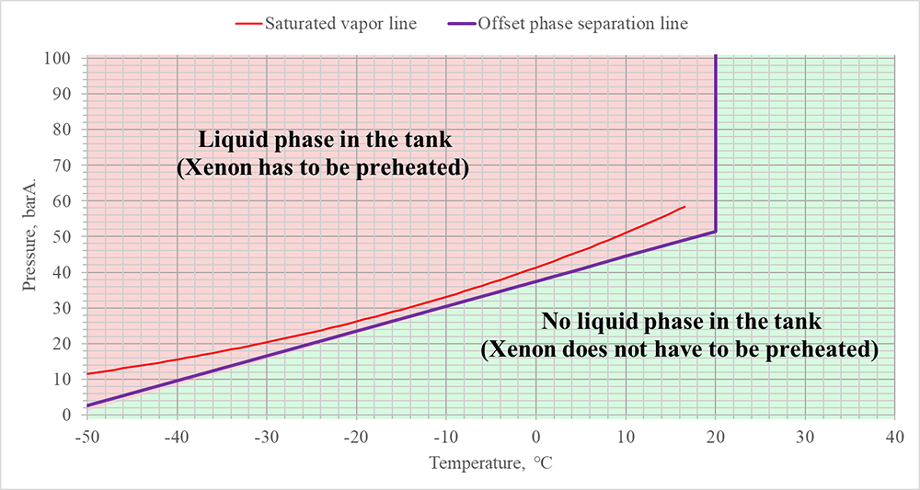

Compared to other noble gases, xenon’s critical temperature (the point at and above which a substance can no longer be compressed into liquid form, no matter how much pressure is applied) is relatively high (289.7 °K) and is within the operating temperature range of an electric propulsion system. When xenon is in liquid form, it requires preheating before use.

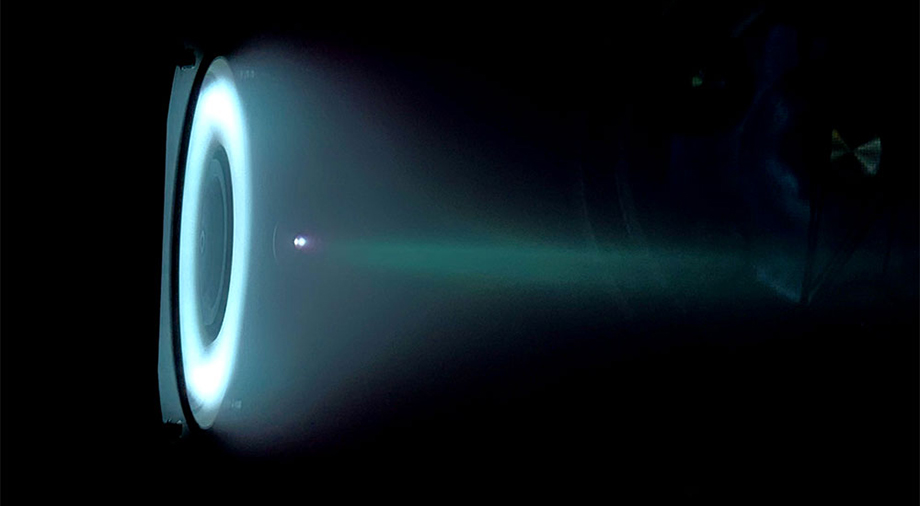

Credit: SETS

Despite this attribute, xenon is the primary propellant for Hall-type electric propulsion systems, as it has a sufficiently high atomic weight, low ionisation energy, and is an inert gas, allowing for high propulsion system performance while maintaining simplicity of operation.

Scientists say switching from xenon to an alternative propellant with lower molar mass, such as argon and krypton, would deteriorate all thruster parameters, except for the specific impulse, which would theoretically increase. Additionally, it would result in changes to the thruster’s design, thereby requiring adjustments and modifications to the propulsion system for the new propellant. Moreover, the thruster’s lifespan when operating on argon or krypton would be shorter than when using xenon (for example, when using krypton, wall erosion rates increased by 1.5-2 times, and rates for argon are expected to be even higher).

Some aspects of krypton or argon have a positive effect on propulsion systems. Since their critical temperatures are only 209.3 °K and 150.7 °K, there is no risk of them entering the feed system in liquid form in the entire operating temperature range. This makes it possible, unlike with xenon propellant systems, to avoid using additional heaters, which allows operators to slightly reduce the total power consumption and simplify the system.

However, since krypton has a lower density than xenon, much larger tanks are required to store the same mass of propellant. Many developers have tried to solve this problem by raising the maximum tank pressure from about 180 bars (traditionally used for xenon systems) to 300-350 bars. But even in this case, the tank volume could be several times larger than for xenon systems. The increased volume and requirements for maximum operating pressure in the tank significantly affect the dry weight and dimensions of the entire propulsion system. In addition, the higher tank pressure of up to 350 bars increases the requirements for the feed system and its components, which in turn complicates the feed system and can lead to an increase in its dimensions.

The disadvantages of argon compared to xenon are even more significant than those of krypton. To store the necessary amount of propellant, it is required to use larger tanks, which can pose a critical issue with spacecraft, where space is limited. Moreover, the lower atomic mass of argon compared to other noble gases can result in less efficiency in propulsion systems, where thrust-to-weight ratios are critical. Moreover, argon’s higher ionization energy requirement could lead either to higher power consumption, or less efficient ionization processes.

It should be mentioned that the use of argon or krypton in high-power thrusters allows for increased thruster efficiency (compared to low-power thrusters) and significantly reduces the costs of purchasing propellants for thruster testing (compared to xenon). The lowest costs for the propulsion system modification for an alternative propellant will come when the thruster operates on an alternative propellant at the same power as the thruster on xenon, since this would remove the need for significant modifications to the PPU.

In summary, transitioning to alternative inert gases, even with thruster optimization for an alternative propellant, would lead to a deterioration of all thruster characteristics other than specific impulse. However, even to achieve specific impulse values comparable to those obtained with xenon, thruster modifications are required. In addition to deteriorating thruster performance and lifespan, switching to krypton or argon can significantly affect the storage and feed system, considerably increasing their dimensions and mass.

Although krypton or argon are much less commonly used than xenon for Hall thrusters, their price makes them attractive propellants for research and use in electric propulsion systems.

Pros of the SETS approach

Our Xenon Feed System (XFS) is an integral component of our Electric Propulsion Systems (EPS) based on Hall effect thrusters. Designed to fulfil two primary functions, the XFS effectively reduces high pressure to working pressure and delivers the necessary mass flow rates to the electric propulsion thrusters. The system comprises various components such as solenoid valves, accumulator tanks, flow restrictors, and fittings, which are meticulously designed and manufactured in-house.

Thus, since most components are manufactured and tested in our production facility, this makes it easier to adjust to the propellant change from xenon to krypton or argon. This approach streamlines production timelines and enables us to tailor the feed system to meet specific parameters, ensuring optimal performance and efficiency.

Overall, the unique combination of characteristics makes xenon the propellant of choice for a spacecraft with the Hall effect thruster. However, krypton and argon could serve as alternatives for specific missions or under certain conditions. Our specially-equipped laboratory and experience in propellant selection allow SETS to evaluate the feasibility of using alternative propellants for missions, as well as to perform tests of various thruster configurations to assess their parameters.