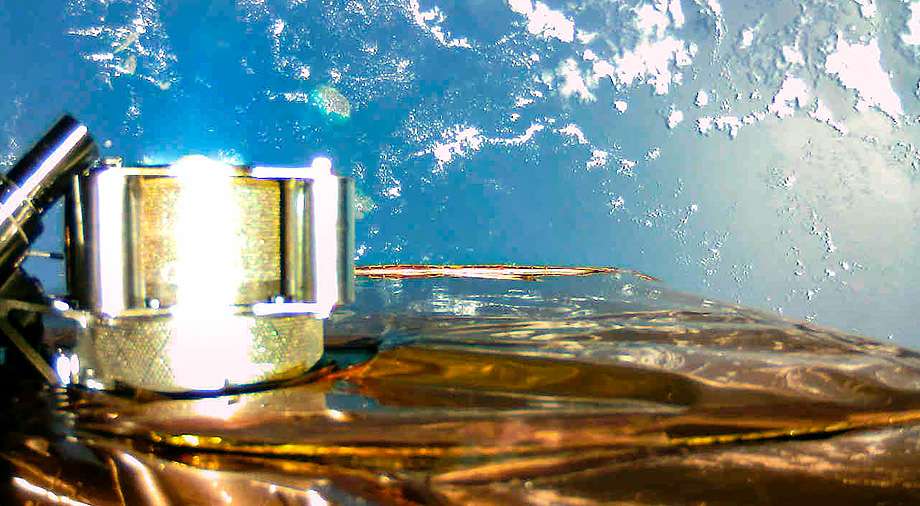

At the start of 2023, the SAT-1 satellite from EOS Data Analytics was launched into orbit. It is the first of seven satellites that will make up a future constellation to support precision agriculture. In addition to being the world’s first target spacecraft designed for agromonitoring, the SAT-1 also demonstrated for the first time the operability of the SPS-25 orbital engine, manufactured by the company Space Electric Thruster Systems (SETS).

Let’s take a look at what makes the electric ion thrusters being developed at SETS so special, and how they are poised to become the leading solution for most orbital satellite missions in the foreseeable future.

The main advantages of electric space propulsion

All electric space engines are based on the principle of converting electrical energy into kinetic energy to accelerate the spacecraft in space. The electric power plant is the “heart” of the engine and is responsible for the process of converting electrical energy into a specific impulse (Delta-v), which is used to accelerate the spacecraft and allow it to assume a designated orbit.

The main purpose of electric space engines is to maintain a spacecraft’s orbital altitude and constant speed. Even the International Space Station (ISS) uses electric propulsion to maneuver for orbital resupply. The atmospheric drag that the ISS encounters while traveling in Earth orbit is steadily pulling the station down toward Earth, so without systematic orbit-alignment maneuvers, the station is at risk of falling out of its working orbit (≈400 km above the Earth) and breaking up in the denser lower layers of the planet’s atmosphere.

Source: NASA

Establishing conditions under which satellites can maintain a constant orbital speed is especially important when it comes to moving satellite constellations, the most popular architecture of complex satellite solutions today. The constant speed created by electric space engines allows satellite constellations to move at the same pace, and also ensures that the satellites can enter their set orbital coordinates at the same time of day. This is especially useful in the monitoring activities of devices aimed in particular at the collection of meteorological data and vegetation indicators in precision farming.

Reasons for abandoning chemical engines

The main alternative to electric space propulsion is the use of chemical propellants. These power plants, although they can provide the spacecraft with much more thrust, are nevertheless far less efficient than electric engines, since they consume much more fuel, thus directly affecting the service life of the spacecraft.

In addition, the microgravity conditions in near-Earth orbit do not require spacecraft to have powerful power plants, since their mass is actually leveled under weightless conditions. Chemical-fueled thrusters are the preferred solution only when launching launch vehicles, because their power allows rockets to overcome the force of the Earth’s gravity. To date, no existing electric space engine has the force necessary to power a launch vehicle into orbit from the Earth.

Moving away from the use of chemical fuel helps to reduce the entire mass of the spacecraft, allowing for the carrying of additional payload. This plays a particularly important role in planning interplanetary space flights. So, an electric-powered spacecraft traveling to Mars will be able to reach its destination carrying about 70% its original weight. For a ship with a chemical-fueled rocket engine, however, this figure would be no more than a few percent of its mass at the time of launch because so much of the ship’s weight would be dedicated to fuel reserves for the long journey.

Types of electric engines

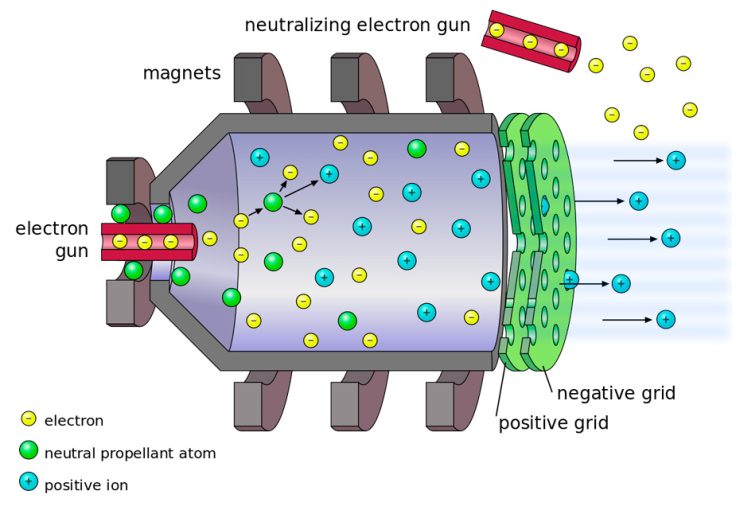

Now the most common types of electric space engines are ion and plasma. These engines create thrust by ionizing fuel with electricity. The most commonly used fuel for ion thrusters is an inert gas like xenon, krypton, argon, or in some cases mercury.

Ion and plasma space engines can be divided into three broad categories by their functional features:

- Electrostatic engines. These engines accelerate ion plasma using an electric field directed behind the spacecraft to push it forward. Thus, ions in electrostatic ion thrusters are always accelerated in the direction of the electric field.

- Electrothermal engines: These engines create thrust by increasing the specific temperature of the fuel when the plasma is exposed to strong magnetic fields. The heat generated is applied to the propellant, which is a low molecular weight gas. The excess heat released during the mixing of the plasma with powder gasses is removed through the engine nozzle, providing the spacecraft with thrust.

- Electromagnetic engines: If in electrostatic engines the acceleration of ions occurs as a result of Coulomb force, then in electromagnetic engines it is achieved using the Lorentz force, which accelerates both free electrons and positively and negatively charged ions (anions). Unlike electrostatic ion thrusters, electromagnetic thrusters accelerate ions in a direction perpendicular to the direction of the applied electric field.

To ensure the smooth operation of electric space engines, they need to constantly replenish the supply of electricity. In areas close to the Sun with high radiation intensity, this problem is solved by installing solar panels on the spacecraft to turn the sun’s rays into electricity. In areas of space more distant from the Sun, ion and plasma engines are used, which generate electricity using the decay of nuclear fuel.

We will focus mainly on ion space engines in this article. However, it should be noted that plasma and ion accelerators are not the only solution for organizing long-term space flights right now.

Photonic (or laser) propulsion systems are currently under development, which provide thrust through a directed beam of photons. Unlike chemical and electric engines, which always carry a supply of fuel on board the spacecraft, the energy source in laser engines is often located outside the ship’s hull (photons are usually delivered to the power plant from ground-based laser stations).

The Hall effect: the forerunner of ion thrusters

The SPS-25 electric engine is classified as a Hall ion thruster because it operates using the Hall effect, named for American physicist Edwin Hall, who first observed the phenomenon in 1879. Hall ran an electric current through a thin semiconductor plate made of gold leaf, and then applied a strong magnet. This resulted in a difference of electric potential on this plate, known as Hall voltage. This principle formed the basis for the functioning of space ion thrusters, the first versions of which began to appear 85 years after the discovery of the Hall effect.

The first idea for creating an electric rocket engine came from Konstantin Tsiolkovsky, a pioneer of rocket and space theory. Later, the inventor of the world’s first chemical-fueled ballistic rockets, Robert Goddard, also endorsed the prospect of building electric-powered rocket engines.

Today’s Hall effect thrusters accelerate low-density ion plasma by subjecting it to a strong magnetic field. Artificially accelerated ions create a specific impulse (Delta-V), which provides a spacecraft with enough kinetic acceleration to perform orbital thruster maneuvers and interplanetary flights.

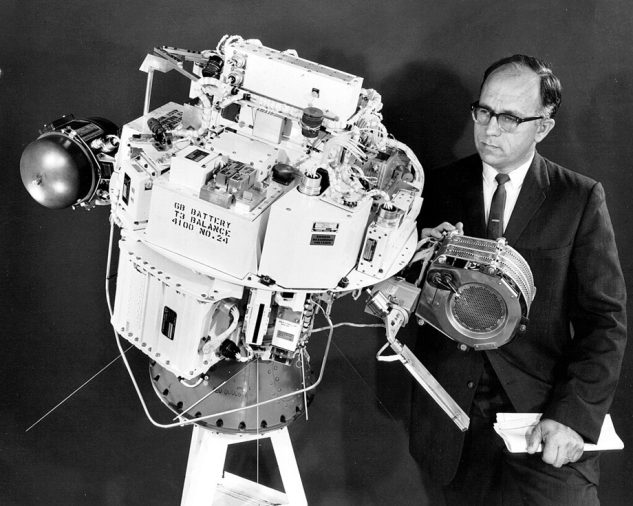

The SERT-1 (Space Electric Rocket Test) marked the first successful electrostatic ion thruster that reached orbit. Launched into space on July 20, 1964, it operated in orbit for just over 31 minutes. The next version of an ion-powered spacecraft, SERT-2, was launched into orbit six years later in 1970. It used two electric ion engines running on mercury fuel. The experiment showed the amazing stability of the technology, as the ion engines were stopped and started about 300 times, and the two engines operated for a total of 2011 and 3781 hours, respectively.

Source: NASA

The historic SERT-1 mission demonstrated the ability to use ion thrusters for interplanetary flights, and by 1998, the spacecraft Deep Space 1, equipped with a more advanced modification of the NSTAR (NASA Solar Technology Application Readiness) ion engine, embarked on its first space mission to make a flyby of asteroid Braille 9969 and the comet Borelli.

The European Space Agency (ESA) also successfully demonstrated the capabilities of its electric jet engine with the flight of its GOCE orbiter, designed for mapping the gravitational field of the Earth, in 2009.

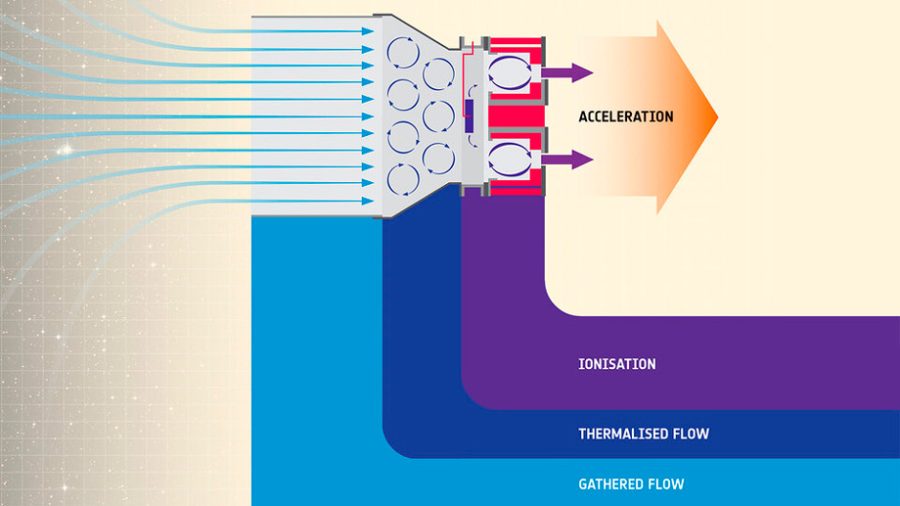

The Ram-Electric Peoplusion electric space engine, developed by the Italian company Sitael, used air molecules in the Earth’s upper atmosphere to create thrust. The engine collected these molecules with a Polish-made QuinteScience air intake.

After entering the air intake, the air molecules were artificially compressed and, using a particle beam generator, entered the GOCE’s electric engine running on xenon fuel. The momentum from the air molecules was strong enough to ignite the engine, allowing the GOCE team to demonstrate the potential performance of their atmospheric fuel engine technology.

The ESA GOCE space mission proved that in the future, technologies like the Ram-Electric Peoplusion engine can be used to organize multi-year orbital missions not only in the earth’s atmosphere, but also in the atmospheres of other planets in the solar system. However, for this, the design of the engine should first be modified to use carbon dioxide molecules, which prevail in the atmospheres of the planets closest to the Earth (Venus and Mars), as fuel.

Simplicity of design and energy efficiency: what makes the SETS ion thrusters special

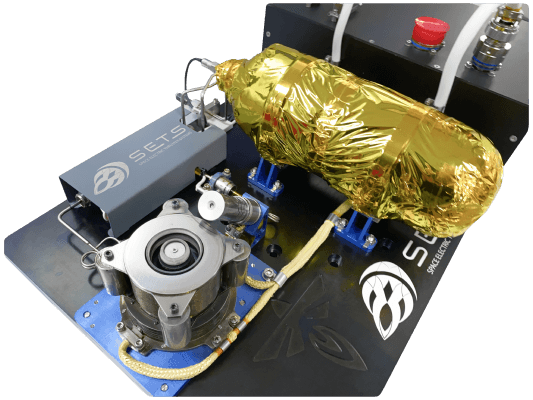

Despite their relatively small size, the SPS-25 engines installed on the EOS SAT-1 constellation satellite can provide thrust with a specific impulse up to 1400 seconds and a power of 200 watts. The SPS-25 power plant is capable of generating thrust from 5 to 11 mN, which is sufficient for the long-term use (in the case of the EOS SAT constellation, a service life of 5-7 years) of satellites in low Earth orbit. The total weight of the power plant is only 6 kg, which allows a significant part of the satellite’s mass to be allocated to its payload in the form of spectral sensors and ultra-sensitive optics to enable the EOS SAT constellation’s satellites to take high-resolution images (up to 1.4 pixels / m).

SETS manufactures all the components of its electric ion thrusters in-house and assembles them into a single power plant. This allows customers to make significant savings of both the time and money needed to create a satellite from scratch. All companies responsible for the development of EOS SAT satellites are vertically integrated with each other as part of the Noosphere, founded by aerospace visionary Max Polyakov. This organization of the workflow minimizes the logistics risks, and also significantly increases the rate of satellite production without harming assembly quality, which ultimately reduces costs.

SETS integrates advanced 3D printing technologies into the manufacture of its engines, which also significantly reduces their production time. The development and assembly of the SPS-25 engine was carried out in Ukraine under wartime conditions, after which the power plant was sent to the workshops of the South African company Dragonfly Aerospace, where the ion engine was installed on the satellite. The entire process of creating SAT-1 took only seven months, which is around half the average market time for assembling this kind of monitoring satellite (1-1.5 years).

The global shortage of electrical components was a complicating factor, but SETS engineers were able to create the SPS-25 system entirely out of commercial components. This is another factor in SETS’s ability to reduce costs and efficiently build its engines. At the same time, all components undergo the necessary tests for operation in cosmic temperatures and radiation, which ensures the engines’ reliability.

The inert xenon and krypton gasses used as fuel in SETS ion thrusters are environmentally friendly, unlike chemical combustion engines, which release harmful emissions into the atmosphere as the fuel burns.

In the foreseeable future, new types of electric space engines will be able to provide 100 km/s of spacecraft thrust (Delta-v), which will open up a unique opportunity for mankind to send their spacecraft to the most distant planets of the solar system. Innovative engines being manufactured in SETS workshops today are at the forefront of this amazing future space exploration.